Pre-Engineered Buildings are the state-of-the-art steel solution to developing an efficient and cost-effective infrastructure. PEB's offer ultimate design flexibility and an extremely shirt construction time (right from initial design to completion). They are supplied as a fully furnished product along with steel structure, roofing, cladding and building accessories. They require no on-site fabrication or welding - they can simply be bolted together as per specifications. PEB's are best suited for warehouses, sports halls, factories. workshops, distribution centers, cold storages, supermarkets, aircraft hangars or any good + multi-storey construction.

STRENGTHS OF PEB STRUCTURES

- Single source responsibility

- Low initial cost

- Engineering flexibility

- Faster overall project completion

- Fast modular expandability

ADVANTAGES OF PEB STRUCTURES

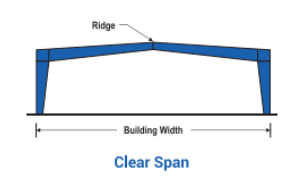

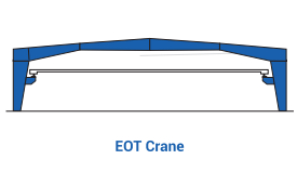

- Clear spans up to 100m without internal columns

- Flexibility in building dimensions

- Easy expansion

- Fixed deadlines and costs

- Weather-tight roof and wall coverings with accessories for long maintanence free exteriors

WHY PEBs are more efficient than conventional RCC / Concrete Buildings

- PEBs that HALF the construction time.

- Usability of the building can be started earlier enabling faster return on investment (ROI).

- Design flexibility and completely customisable in shape, cost and use.

- Superior aesthetic value, better rain water drainage and connect to RCC structure.

- Savings in cost of civil work. PEBs are lighter in weight thereby requiring lesser civil work

- No site fabrication required. Site work is minimized and largely hassle-free.

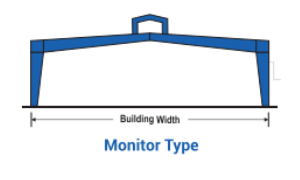

- Vertical clearance from the floor can increase significantly from eaves to ridge creating more volumetric parameter.

- PEB can be dismantled, at ease and can be re-erected at a totally different location.

- Entire gamut of activities starting from inception to completion are being undertaken by a single entity resulting in efficient project control.

Cost & Time Effective

Strong & Durable

Tailor-made Solutions

Flexible & Adaptable

Can Withstand Against Natural Disasters

Expandable & Quickly Erectable

Eco-friendly & Energy Efficient

Structural Frames

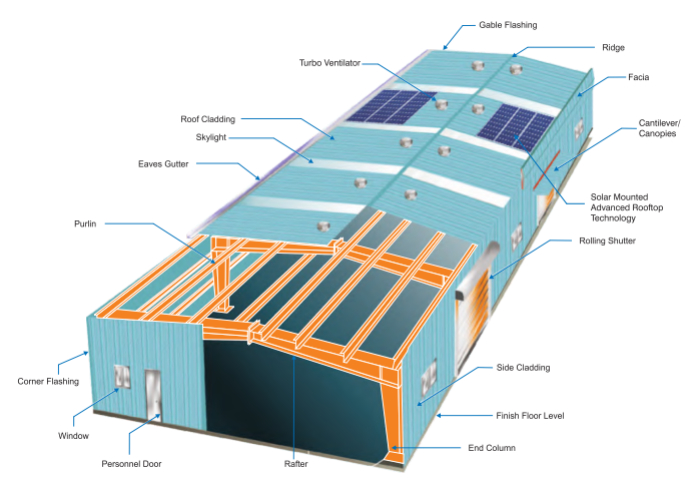

Multicolor Pre-engineered buildings are custom designed to meet your exact requirements. The basic defining parameters are:

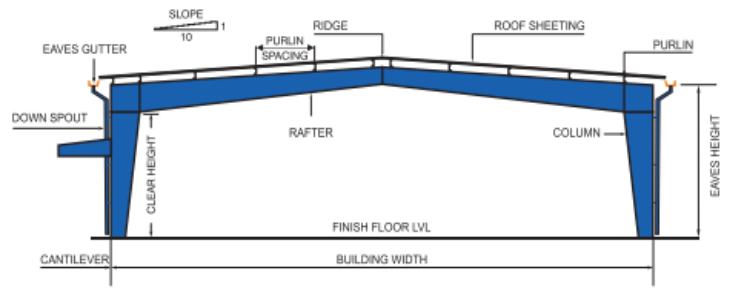

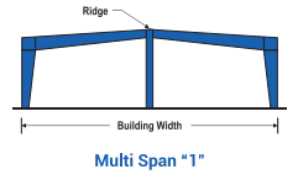

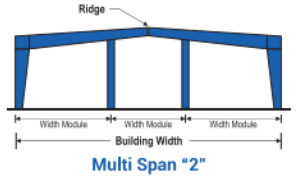

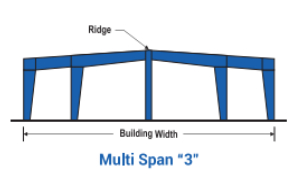

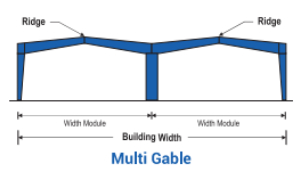

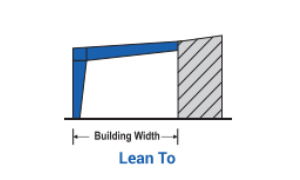

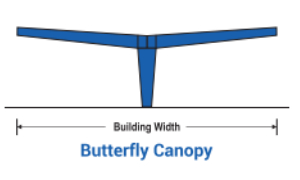

Building Width

No matter what primary framing system is used, this is defined as distance from the outside of main framed column of one side wall to the outside of mail framed column of the opposite side wall.

Building Length

It is the distance between the outside line of one side gable end column (end wall) to the outside line of gable end column (end wall) of the opposite side. Any length is possible.

Building Height

It is the eave height which usually is the distance from the bottom of the main framed column base plate to the top cap plate of the main framed column. When the columns are elevated from finished floor level, building height is the distance from finished floor level to the top of cap plate of the main framed column.

Bay Spacing

This is the distance between the centerline of two adjacent interior main framed columns

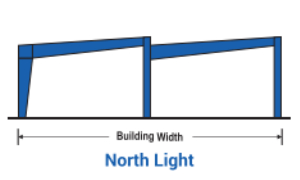

Roof Shape

This is angle of roof with respect to the horizontal. The most common roof slope is 1:10. Any practical roof slope is possible.

Clear Height

This is the distance between the finished floor level to the bottom of knee joint.

Roof Cladding Frames

RKB is manufacturing and supplying a wide rang of colour coated and aluminum — zinc coated roofing sheets, The sheets are manufactured using high-quality raw materials and are UV protected to prevent heat. These unbreakable sheets are largely appreciated for long service life, light weight, low flammability and impact resistance, this sheets are tested on various parameters for their optimum quality.

Bare Galvalume PPGL PPG!

0.4 mm to 1 mm

1 mm 250, 300, 350 & 550 MPA

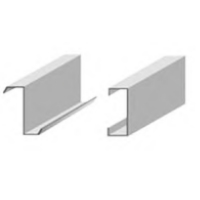

C&Z Purlin Sections

Hot Rolled (HR) Cold Rolled (CR) Galvanised

1 mm to 4 mm

200, 250, 300 & 350 MPA

'Z' Purlin

100 mm to 250 mm

45 mm to 75 mm

15 mm to 20 mm

'C' Purlin

100 mm to 250 mm

45 mm to 75 mm

15 mm to 20 mm

| STEEL MATERIAL | SPECIFICATION | MINIMUM YIELD STRENGTH |

|---|---|---|

| PRIMARY MEMBERS PORTAL FRAMES / BUILYP FRAMES |

ASTM A570 G 50/IS8500 or Equivalent | YS 345 mpa |

| SECONDARY MEMBERS COLD FORMED HR STEEL & GALVANISED STEEL |

ASTM A570 or IS1079 . 10748 ASTM A653 MSSGR. 34, COATING 150/180 GSM |

YS 245 or 345 mpa & YS 345 |

| ROOF SHEETS & PANELS BARE GALVALUM & COLOUR COATED |

ASTM A792M Grade D AZM150 | YS 345 or 550 mpa |

| VALLEY GUTTER GALVANISED STEEL |

IS 513 Grade 0 or D | YS 240 mps |

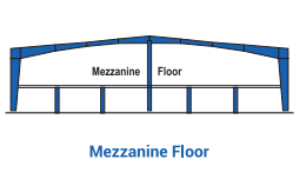

| MEZZANINE DECK PANELS GALVANISED STEEL |

ASTM A 653 SS Grade 55, ZINC COATING 180 GSM | YS 550 mpa |

| DIAGONAL BRACING MEMBERS ROD ROUND BAR |

ASTM A 36M / IS2062 or Equivalent | YS 245 mpa |

| High Strength Bolt (rafter) | ASTM A 325M Grade 8.8 or Equivalent | UTS 830 |

| Anchor Bolt (rafter) | ASTM A 36M / IS2062 or Equivalent | YS 245 mpa |

| Galvanised MS BOLTS | ASTM A 36M / IS1367 or Equivalent | YS 245 mpa |

Our Projects